Coatings (WoS, Q2, IF=2.881), 2021, Volume 11, Issue 5, 532

Abstract. The study is devoted to the development and testing of technological principles for the manufacture of solid end mills from ceramics based on a powder composition of α-SiAlON, β-SiAlON, and TiN additives, including spark plasma sintering powder composition, diamond sharpening of sintered ceramic blanks for shaping the cutting part of mills and deposition of anti-friction Si-containing diamond-like carbon (DLC) coatings in the final stage. A rational relationship between the components of the powder composition at spark plasma sintering was established. The influence of optimum temperature, which is the most critical sintering parameter, on ceramic samples’ basic physical and mechanical properties was investigated. DLC coatings’ role in changing the surface properties of ceramics based on SiAlON, such as microrelief, friction coefficient, et cetera, was studied. A comparative analysis of the efficiency of two tool options, such as developed samples of experimental mills made of SiAlON/TiN and commercial samples ceramic mills based on SiAlON, doped with stabilizing additives containing Yb when processing nickel alloys (NiCr20TiAl alloy was used as an example). DLC coatings’ contribution to the quantitative indicators of the durability of ceramic mills and the surface quality of machined products made of nickel alloy is shown.

Keywords. Diamond-like carbon coating; high-speed milling; nickel alloy; SiAlON; spark plasma sintering; roughness; wear resistance.

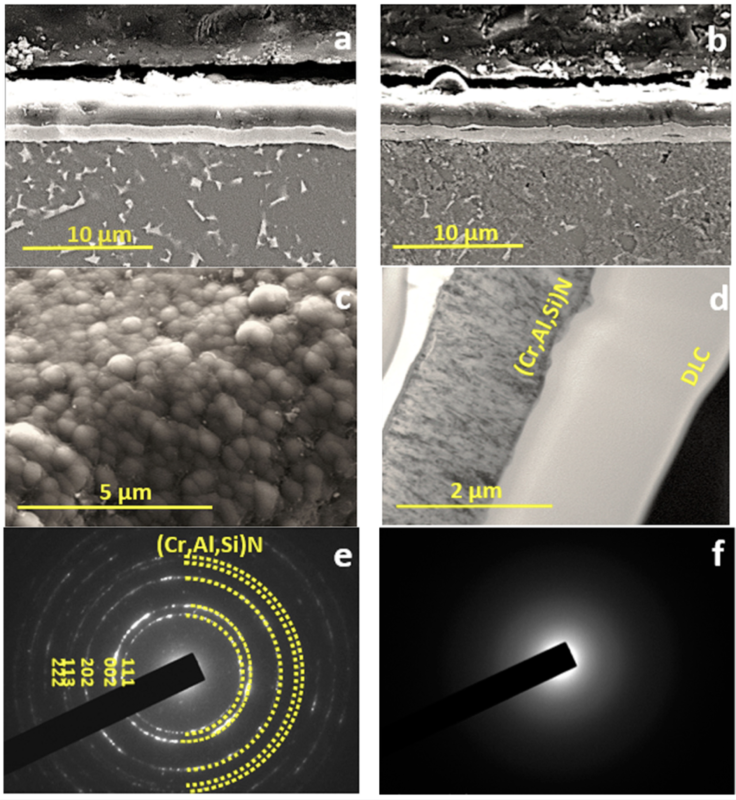

Microstructure of ceramic specimens with DLC coatings: (a) SEM image of a thin section of an experimental specimen 80% (90α10β) + 20% TiN ceramics with DLC coating; (b) SEM image of a thin section of commercial ceramics specimen with DLC coating; (c) SEM image of the DLC coating surface structure; (d) TEM image of the a two-layer DLC coating structure; (e) SAED of the (CrAlSi)N sublayer; and (f) SAED of the functional DLC layer.

Исполнители: Grigoriev, SN; Volosova, MA; Fedorov, SV; Okunkova, AA; Pivkin, PM; Peretyagin, PY; Ershov, A

Дата публикации: 22-10-2021

Источник: https://www.mdpi.com/2079-6412/11/5/532