Mechanics & Industry. Volume 17, Number 7, 2016. WoS

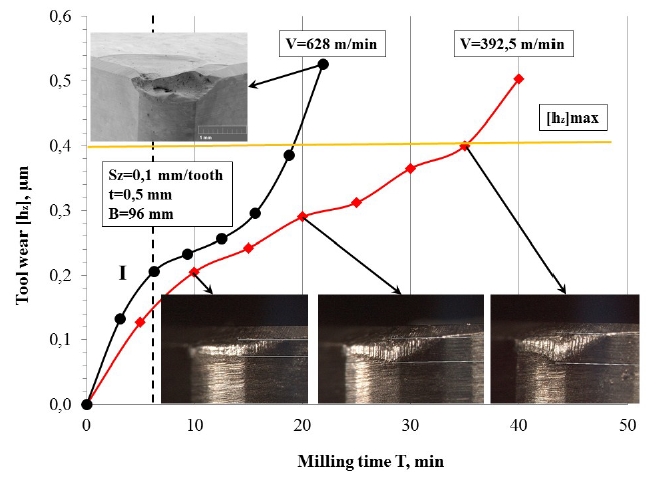

Abstract The article considers the substitution of silver in interrupting electrical contacts by a non-precious metal on the basis of copper. Technical specifications for the material capable of replacing silver are formulated, including high softening temperature and weak adhesion of oxides to the base metal. As a result, a composite nanomaterial on the basis of copper is offered to substitute silver. Microstructure, mechanical, thermî-mechanical, physical properties of the nanocomposite was studied. Changes of contact resistance during the formation of oxides on the surfaces of copper, silver, and the nanocomposite was studied, as well as losses of volume when exposing these materials to an electric arc. The prospects of substituting silver by the nanocomposite on the basis of copper were proven by the results of comparative bench testing of materials.

Key words: Electrical contacts / silver / copper nanocomposite / properties / electric arc / wear / contact resistance

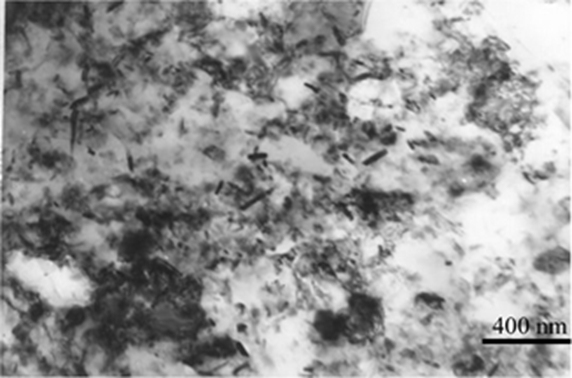

Subgrain structure of the nanocomposite Cu-Al2O3.

Исполнители: Iosif S. Gershman, Eugeniy I. Gershman and Pavel Yu. Peretyagin

Дата публикации: 30-11-2016

Источник: https://www.mechanics-industry.org/articles/meca/abs/2016/07/mi160249/mi160249.html